No products in the cart.: $0.00

Value Added Secondary Operations

- Home

- Value Added Secondary Operations

Injection Molding Value Added Services

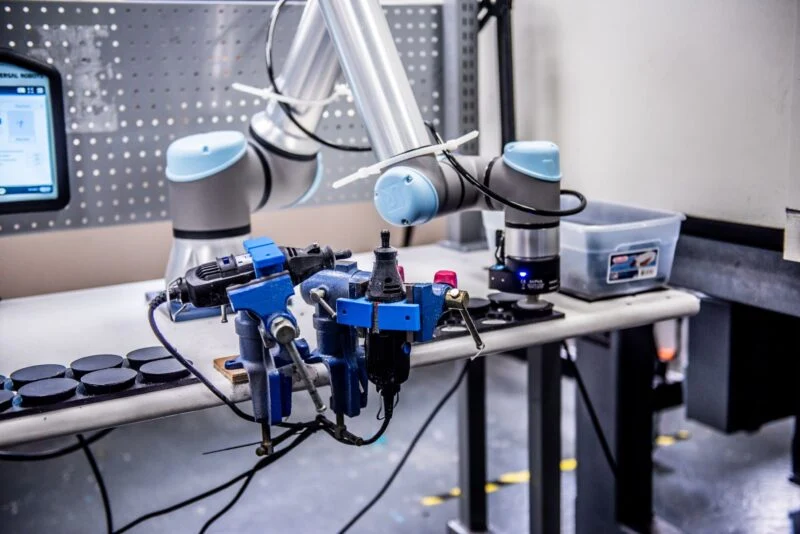

We are always on the lookout for ways to elevate the injection molding experience for our clients. This includes simplifying and automating post-molding tasks and delivering cost-efficient solutions through our secondary services.

Post-Molding Secondary Operations Include:

Adhesives: Like liquid silicone rubber, adhesive silicone gels are also known for their durability, flexibility, and resistance to extreme environments. They can be used in many different industries and create strong chemical bonds to liquid silicone rubber. Through various techniques, Extreme Molding has been applying silicone gels secondarily to medical, consumer, and female healthcare products for nearly two decades.

Post-Curing: Post-curing (post-baking) silicone is an important step in the manufacturing of silicone products. This process involves exposing the silicone to elevated temperatures for extended amounts of time using calibrated equipment after the products have been molded. This process may be necessary to complete the final cure of the product, improve mechanical properties, improve heat resistance, and meet other biocompatible and regulatory requirements set forth by a customer.

Die Cutting/Hole Punching/Slitting: Our post-molding services also include die cutting, hole punching, and automated slitting. With our die cutting service, we can transform your silicone part into an array of shapes, designs, or patterns. For cases where in-mold operations aren’t feasible, we provide hole punching services, particularly for creating small-diameter holes in products like bottle nipples. We also offer customized options for slitting, including various configurations such as Y-Slit and X-Slit, tailored to your exact specifications.

Additional Services: Assembly, Fulfillment and Packaging, Laser Etching, Pad Printing.

What to Expect

When you make your silicone product with us, our engineers will work with you to identify any die cutting, adhesives or other secondary operations you may need for your product.